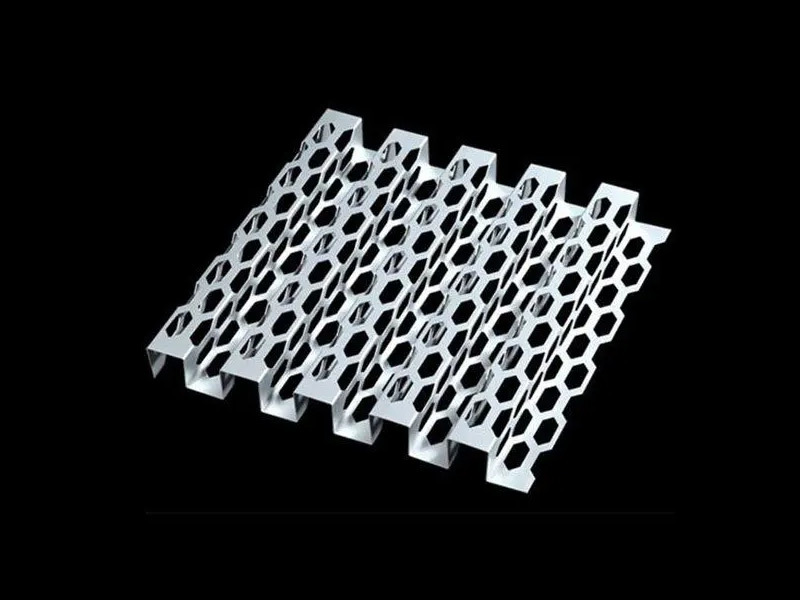

Punched special-shaped aluminum veneer

Key words:

Classification:

Tel:

Punched special-shaped aluminum veneer

Punching ceiling is the use of computer numerical control stamping equipment, selection of high-quality metal materials, with different specifications or flowers of the punching process to beautify the metal plate surface, can relieve the depression caused by the closure, looming, broaden the field of vision space sensory. Its elegant appearance, excellent corrosion resistance, fireproof and moisture-proof, durable, not affected by positive and negative pressure, is conducive to the heat dissipation and lighting of vents or other equipment.

Characteristics of aluminum veneer

1. Light weight, good rigidity and high strength 3.0MM thick aluminum plate weighs 8KG per square plate and has a tensile strength of 100-280N/MM2.

2. Good durability and corrosion resistance. Using KYNAR-500,HYLUR500 as the base material of PVDF fluorocarbon paint, can be used for 25 years without fading.

3, the process is good. Using the first processing and then painting process, the aluminum plate can be processed into a variety of complex geometric shapes such as plane, arc and sphere.

4. Uniform coating and diverse colors. Advanced electrostatic spraying technology makes the adhesion between the paint and the aluminum plate uniform, color diversity, the choice of space.

5, not easy to stain, easy to clean and maintain. Fluorine coating film non-adhesive, so that the surface is difficult to adhere to pollutants, more good to clean.

6. The installation and construction are convenient and quick. The aluminum plate is formed in the factory, and the construction site does not need to be cut and fixed on the skeleton.

7, can be recycled, conducive to environmental protection. Aluminum plate can be 100 recycled, different from glass, stone, ceramics, aluminum-plastic plate and other decorative materials, high recovery residual value.

Online consultation

Related Products